BRM Announces Cylinder Hones For Surface Finishing Main Bearing Bores; Flexible Honing Improves Lubrication And Heat Dissipation While Reducing Friction

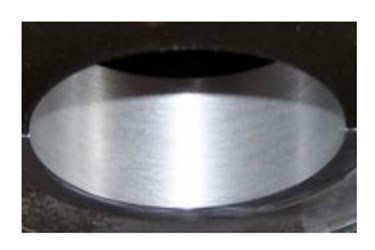

Brush Research Manufacturing (BRM), maker of Flex-Hone® tools and a full line of industrial brushes, announces plateau hones for main bearing bores. BRM ball hones create a cross-hatch pattern of peaks and valleys that improve lubrication and heat dissipation while reducing friction in main bearing tunnels, engine components where main bearings are seated and that help crankshafts turn.

Los Angeles, CA (PRWEB) - Brush Research Manufacturing (BRM), maker of flexible honing tools and a full line of industrial brushes, is announcing a new application for its Flex-Hone® tool. Automotive mechanics and engine restoration specialists are using the American manufacturer’s cylinder hones to improve the surface finish of main bearing bores, critical components for optimizing engine rebuilds.

According to COME Racing, an Australian manufacturer of high-performance auto parts, main bearing tunnels must meet tolerances for size, roundness, taper, and surface finish. Line boring with a mandrel is recommended for cylinders that are out-of-round or require significant material removal. For a superior surface finish, however, mechanics and engine builders are using the Flex-Hone® tool from BRM.

Plateau Hones and Cylinder Surface Finish

Self-centering and self-aligning to the bore, BRM’s plateau hone is versatile and easy-to-use. For years, do-it-yourself (DIY) mechanics and professional engine tuners have used the ball hone to deglaze and surface finish engine cylinders. Now, car enthusiasts and professional automotive mechanics alike are using this flexible engine hone to impart a superior surface finish to main bearing bores.

As MSG Tuning, another Australian automotive company, explains, “Good contact between bearing shell and bore will not be possible with a surface that does not have a plateau finish.” This uniform series of peaks and valleys, or cross-hatch pattern, allows the crankshaft to turn with less friction while gripping the bearings effectively and dissipating heat efficiently.

BRM Flexible Honing Tools

With cast iron engine blocks, MSB Tuning uses an 800-grit Flex-Hone® with silicon carbide (SC) abrasive. For alloy engine blocks, the engine builder chooses 800-grit cylinder hones with aluminum oxide (AO) abrasive. Although BRM’s flexible hones aren’t meant for heavy-duty material removal, MSB Tuning also uses coarser-grit Flex-Hone® tools for more aggressive honing.

For best results, Brush Research Manufacturing (BRM) recommends starting with a coarser-grit Flex-Hone® and finishing with a finer-grit tool. Always use BRM’s flexible hone with a lubricant (preferably BRM’s specially-formulated Flex-Hone® oil), and never over-hone.

About Brush Research Manufacturing

Brush Research Manufacturing (BRM), makers of a full line of flexible honing tools and industrial brushes, is located in Los Angeles, California. Since 1958, BRM has been solving difficult finishing problems with brushing technology. Download the Flex-Hone® Resource Guide for information about how to choose and use flexible honing tools.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2013/7/prweb10891064.htm