BRM Announces New Resource For Choosing Abrasives And Grits For Flexible Hones; Full-Color Guide Explains Abrasive And Grit Types For Surface Finishing

Brush Research Manufacturing (BRM), maker of Flex-Hone® tools and a full line of industrial brushes, announces a new technical book for manufacturers, machinists, and metalworkers who need help selecting abrasives and grits for BRM cylinder hones. The Flex-Hone® Resource Guide explains which abrasive and grit type to choose for deburring, edge blending, and surface finishing a variety of metals and other base materials with BRM ball hones.

Los Angeles, CA (PRWEB) - Brush Research Manufacturing (BRM), maker of flexible honing tools and a full line of industrial brushes, is announcing a new resource for Flex-Hone® users who need help choosing abrasive and grit options for BRM ball hones. Ideal for burr removal, edge blending, and improving the internal surface finish of bores and cylinders, BRM brush tools are both versatile and easy-to-use.

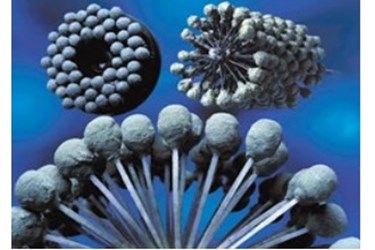

Flex-Hone® tools mount in machine centers, lathes, drill presses, and handheld electric drills for applications including burr removal from cross-drilled holes and slots. With its low-temperature abrading process and soft cutting action, BRM’s flexible honing tool features balls of abrasive grit that are permanently laminated to the ends of flexible nylon filaments.

How to Select Flex-Hone® Abrasives

For the manufacturers, machinists, and metalworkers who trust BRM cylinder hones to impart the ideal surface finish, Flex-Hone® selection means choosing the right abrasive and grit options. Today, these BRM brush tools are manufactured in 8 different abrasive types and 11 different grit options for use with a variety of base materials and surface finish requirements.

BRM recommends aluminum oxide (AO) abrasive for deburring, edge blending, and surface finishing aluminum, brass, bronze, and softer metals. For deglazing Nikisil cylinders, the California company’s technical services team suggests 240 AO. Boron carbide (BC) abrasive is suitable for medium to high carbon steels, heat-treated steels up to 50 Rc, and with titanium.

For mild steel, stainless steel, and cast iron, use Flex-Hone® tools with silicon carbide (SC) abrasive. For low carbon to medium carbon steels, choose zirconia alumina. BRM cylinder honing tools with Z-grain abrasive can also be used to deburr and surface finish stainless steel and cast iron – and for applications that require longer tool life than silicon carbide provides.

BRM ball hones with tungsten carbide (WC) abrasive are ideal for high carbon steel alloys and exotic space age alloys used in aerospace and defense applications. For a final finish on many base materials, levigated alumina abrasive is often the right choice. For carbide, ceramic, hardened tool steel, and heat treated steels, however, BRM recommends the Diamond Flex-Hone® for deburring and surface finishing.

Flexible honing tools that use cubic boron nitride (CBN) or ceramic abrasive are available by special request for use with harder materials. Flex-Hone® users who aren’t sure of their tool’s abrasive type can look for a colored dot on the tool’s stem. A colored dot near the flexible hone’s tip indicate grit type.

Grit Types and Abrasive/Grit Options

Choosing the right grit for a BRM brush tool depends upon the amount of work to perform and the degree of improvement that’s required. Often, coarse finishes require progressively finer flexible honing tools to meet final surface finish requirements.

Silicon carbide, aluminum oxide, and boron carbide Flex-Hone® tools are available in the following grits: 20, 40, 60, 80, 120, 180, 240, 320, 400, 600, and 800. Tungsten carbide tools are available in all but 400, 600, and 800 grits. BRM diamond honing tools are available in mesh 170/200, 800, and 2500 while levigated alumina ball hones come in extra fine grit only.

Download the Flex-Hone® Resource Guide for complete information about how to choose and use flexible honing tools.

About Brush Research Manufacturing

Brush Research Manufacturing (BRM), makers of a full line of flexible honing tools and industrial brushes, is located in Los Angeles, California. Since 1958, BRM has been solving difficult finishing problems with brushing technology.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2013/7/prweb10925545.htm