BRM Announces Cylinder Hones For Automated Bore Finishing And Blending; Flexible Honing Tools Reduce Cycle Times And Improve Surface Finish

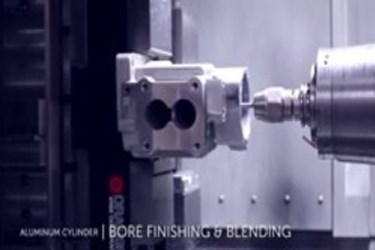

Brush Research Manufacturing (BRM), maker of flexible hones and high-performance industrial brushes, announces cylinder honing tools for automated bore finishing and blending. BRM invites manufacturers to watch the Flex-Hone® In-Machine Setup for Surface Finishing and Deburring video, and learn how automated flexible honing can improve efficiency and quality.

Los Angeles, CA (PRWEB) - Brush Research Manufacturing (BRM), maker of Flex-Hone® tools and pioneer of plateau finishing, is announcing cylinder honing tools for automated surface finishing and deburring operations. The Flex-Hone® tool is a flexible, resilient honing tool that improves the surface finish of cylinders and removes cut, torn, and folded metal (burrs) that can impede performance.

Built with a metal stem and flexible nylon abrasive filaments, BRM cylinder hones mount in lathes, mills, drill presses, and electric hand drills. By using flexible honing tools with machine centers, manufacturers can replace off-hand or manual deburring with faster, more efficient, uniform operations. Self-centering and self-aligning to the bore, Flex-Hone® tools are also self-compensating for wear.

Flexible Honing Improves Quality, Speeds Operations

As the Flex-Hone® In-Machine Setup for Surface Finishing and Deburring video explains, flexible hones follow existing bore geometry and will not affect size, ovality, or concentricity. Unlike other automated deburring tools, BRM cylinder hones do not require rigid setups. Flex-Hone® tools in machine centers can be used to surface finish cylinder walls made of various metals, including 6061 and 7075 aluminum.

Automated honing with the Flex-Hone® tool is ideal for bore finishing and blending, as well as cross-hole deburring and port radiusing. By removing the peaks produced by prior machining operations, cylinder honing allows piston rings to seat and seal without damaging their edges. The substantially flat surface that the Flex-Hone® imparts also promotes longer seal life, increases bearing area, and reduces wear.

Plateau Finishing for Optimum Lubrication

By creating a series of uniformly-spaced, oil-retaining grooves, cylinder hones also optimize lubrication while reducing seepage in hydraulics. Industries and applications that use Flex-Hone® technology to solve surface finishing challenges include automotive, aerospace, earth moving equipment, marine, oil and gas, aluminum extrusions, brass instruments, fluid and power, and military and defense.

Available in a 10 different abrasive types and a wide range of grit selections, BRM cylinder hones come in standard diameters ranging from 4-mm to 36 inches. For more information about flexible honing and how automated surface finishing and deburring can save manufacturers time and money, watch the Flex-Hone In-Machine Setup video and download the Flex-Hone® Resource Guide.

About Brush Research Manufacturing

Brush Research Manufacturing (BRM), makers of flexible honing tools and a full line of industrial brushes, is located in Los Angeles, California. Since 1958, BRM has been solving difficult finishing problems with brushing technology. BRM’s Flex-Hone® tool is the standard against which all other surface finishing tools are compared.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2013/8/prweb11063882.htm