Aerospace/Airline Plating & Metal Finishing Forum: Trivalent Liquid Chromate and ANC Zinc Processes are Highly Efficient

Continental Surface Treatment, Inc., (Cleveland, OH), has been busy. First, its patent-pending CST Chromiting trivalent liquid chromate is a liquid concentrate with a slight precipitate. It is entirely free of hexavalent chromium or chrome(VI) as well as other toxins and carcinogens.

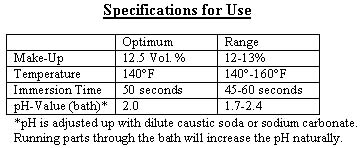

The Chromiting product exceeds the specifications of ASTM B117, however, the company recommends the use of a topcoat, such as CST 555, to increase corrosion protection to 200 h barrel and up to 600 h rack to 5% white corrosion. According to the company, Chromiting can be done with conventional equipment and methods along with rinsing and hot air drying.

If a steel tank is used, it should be lined with an acid-resistant plastic coating. The parts are coated using part agitation or air agitation and the company recommends installing a recovery system to not only minimize drag-out losses but also to save costs as Chromiting is a very highly concentrated chemical.

CST is involved in a joint venture with P&J Industries, Inc., a plating firm based in Toledo, OH. Working together, the two companies have coated turbine nozzles for the aerospace industry as well as many parts for the automotive industry. The trivalent chromium "green" finish (not only is it more environmentally friendly than its hexavalent cousin but it really does leave a greenish color behind) and black chromate finish are among the newest offerings from this pairing.

The second innovation to come from CST recently also works with the Chromite process. Called ZinConium 2000, this ANC zinc process provides a unique zinc deposit that promotes higher corrosion resistance, according to the company. Ideal for both rack and barrel applications, ZinConium produces a fine-grained, ductile, pore-free zinc deposit with 0.8% to 1.0% carbon content.

Platers can also apply this one-component system on cast iron, offering a new and different substrate for additional applications. A one-component brightener system can be easily analyzed if need be and is stable at higher temperatures. Really, the entire system simplifies the zinc plating process by providing blister- and pore-free deposits that can be applied over a wide temperature range -- 75°F to 85°F -- with excellent coverage. Just make sure you ventilate your facility well.

For more information, contact Continental Surface Treatment, Inc., PO Box 81873, Cleveland, OH 44181. Phone (440) 239-9710; Fax (440) 239-9705.