Coating Alternatives Guide Helps With Environmentally Friendly Finishing

CAGE, The Coating Alternatives Guide, is a pollution prevention tool for paints and coatings users. The cornerstone of the site is an expert system designed to recommend low-volatile organic compound/hazardous air pollutant coatings that may serve as drop-in replacements for a user's existing coating operation. There is also an up-to-date information base on various coating alternatives.

Developed by the Pollution Prevention Program at Research Triangle Institute in cooperation with the US EPA Air Pollution Prevention and Control Division (APPCD), CAGE provides information that covers nearly everything a coatings applicator needs to know about environmental compliance in their business location. It provides informational resources for almost every facet of the coatings business.

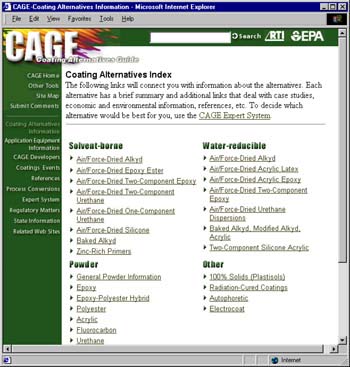

Coatings Systems

The coatings systems information is organized by system type – solventborne, water reducible, powder and other, encompassing nearly every economically viable system available for use today. For instance, solventborne includes everything from air dry and baked alkyds to zinc rich primers. Water reducible runs the gamut between air dry and baked alkyds to two-component silicone acrylics. Powders include epoxies, nylons, PVC and others. In many ways the most interesting section is the "other" classification, including 100% solids plastisols, rad-cures, auto- and electrophoretics. Up to date? You bet.

Application Technology

Of equal importance to the type of coating being applied, the various methods of application are fully described with references and links to additional information. This section is broken down by technology type -- non-spray technologies, spray, and electrostatic technologies. The non-spray section includes dip, flow, dip/spin and direct and reverse roll coating techniques. The spray section is a good place to compare conventional air atomization with airless, air assisted airless and HVLP. There is even a subsection for flame spray coating. Electrostatics covers conventional spray and rotary atomization.

References

The reference section contains a number of articles covering coatings and their constituents, application equipment, the effect of various process parameters, a description of paint defects (and how to troubleshoot them) and an article on coatings testing methods and their meaning. These are all available for download in the familiar Adobe Acrobat (.pdf) format.

The Expert System

The heart and soul of the site is the expert system, which has the capability of accepting data on the user's present application process, and suggesting other compliant processes that will drop directly into their manufacturing venue.

The concept of an expert system is not new, and they exist on the Internet for nearly every purpose from timing the cooking of a beef roast to selecting interconnect cables for your stereo system. Most that are available are simple, and cover a very small number of process variables. Not so with the CAGE system.

To most effectively make use of the Cage expert system, one must first collect data on the present process and substrates being coated. Once this data is complete and the user logs onto the system, he is faced with about 12 screens of data input. The data is input into the system on a series of short, easy to manage pages that ask questions about the kind of coating currently used, the material of construction of the part being coated, process details, price sensitivity and areas of the process the user is willing to change.

For instance, suppose the object is to apply a coating to a complex plastic part. The user logs on, enters his name, company, part number and description, and is asked the following questions, that are each answered by inputting a number, clicking a radio button (multiple choice) or selecting data from a drop-down menu. (Some questions were left out for the sake of brevity and clarity.)

• Must the finished part be conductive?

• How is the part fabricated?

• Will the coating have metal or mica flakes?

• Are there any defects in the part?

• Are there any existing coatings on the part?

• How was the part cleaned?

• How many parts are coated in a given time period?

• Rate the complexity of the part on a scale of 1-5?

• What is the function of the coating?

• What application method will be used?

• Required dry film thickness?

• Number of coats?

• Cure method used?

• What type of pollution control methods are currently used?

• What is the customer's price sensitivity?

• What is the importance of several coatings performance properties?

• How is the user willing to change the process?

There are many more questions that go into additional detail, but suffice it to say that information input for the prepared user should take only about 10 minutes, even for a complex application. The system attacks the thought process just like the user would, but the logic table, which the user would have to develop, is already there. All the user needs to do is hang the variables on hooks in the logic table. Once all the information is input, the user clicks the button to process the application. In about 45 seconds, the application is processed and applicable substitute systems are listed, along with all of the input information on a printable page. The alternative systems are rated on an applicability scale of 0 to 100 points, 100 points being the best possible alternative for the current process.

The convenience of the system is in the printed report. It allows the user to easily make substitutions for current parameters and return data on several "what-if" scenarios. The expert system can take weeks off compliance research. The coatings applicator is ill advised to live without it.

Economics

So, after the user lays the groundwork in choosing an alternative system, what is the first question asked by upper management? Surely, "what is it going to cost?" Soon, a new expert module will be introduced on CAGE that will answer this question, also.

The purpose of the Process Conversion tool on CAGE is to help the user better understand the costs involved in a conversion to a different technology. Also, users can get a good idea of what other factors to consider in converting an existing coating process to a different coating technology. Is a total conversion necessary? Will partial conversion be more economically feasible? What is the best way to phase in total conversion?

The setup of the page will involve a list of coatings technologies with a process conversion link next to each. Clicking on one of these links will provides the user with a list of inputs related to costs involved in converting a coating process. After filling in these inputs, the user then clicks on the calculate now button to get a summary output of annualized costs on a surface area coated per year basis. Small pop up windows are provided for user convenience if the input or output parameter is unclear.

In using the tool, however, keep in mind that this conversion tool is designed to provide a quick and easy estimate of costs related to a process conversion. It is not intended to give the user exact answers nor exact costs of a particular process conversion. Further investigation is necessary, but at least the user knows what alternatives to investigate. Again, this can net a huge time and work savings to an individual wanting to change a coating process, as well as a way to make sure that they are taking all fixed parameters into account.

Other Features

In addition to all of this information, the CAGE site also provides names and addressed to regulatory and other government business agencies by state, so that the user can get all of the necessary information on regulations, possible tax credits or other business aid that should be considered when fine tuning their alternative conversion plans.

The site also provides links to various industry publications that may contain additional information useful in the conversion, including paintandcoatings.com.

Given the regulatory climate today, CAGE provides a comprehensive, easy-to-use solution for converting from a non-compliant to compliant coating system, or between compliant systems for reasons of economy. To check it out, follow this link, www.cage.rti.org, or click the CAGE button on the paintandcoatings.com homepage, Surface Finishing.com's sister site.

For more information on CAGE, contact:

Dean R. Cornstubble

Research Chemical Engineer

Research Triangle Institute

3040 Cornwallis Road, P.O. Box 12194

Research Triangle Park, NC USA

Phone: (919) 541-6813

FAX: (919) 541-7155

Email: dean@rti.org