Electroceramic Coating Boosts Light Metal Properties

By Mark Hull

Ceramic layers produced on aluminum, magnesium and titanium by a novel plasma electrolytic oxidation technology offer an attractive alternative to hard anodized and conversion coatings such as plasma spraying, in-wear resistant and corrosion-resistant applications. Composite and multi-layer coatings incorporating lubricious or additional hard phases are also available.

The coatings are marketed under the trade name Keronite. Worldwide patent rights for the process are held by the licensing and development company, Isle Coat Ltd.,, a subsidiary of CFB plc. The technology is being commercialized under license by A.T. Poeton in the UK and Micron srl in Italy.

Industrial trials in the textile sector have been conducted on Keronite-coated aluminum components, and the process is being actively examined for aerospace and automotive applications. It has also recently emerged as a straightforward, environmentally friendly pre-treatment for magnesium alloys. With existing treatments such as chromating, obtaining good adhesion of paint and other coatings on magnesium can be problematic. Existing treatments often involve toxic chemicals and/or the need for special handling equipment (for example, to avoid atmospheric exposure between pre-treatment and coating).

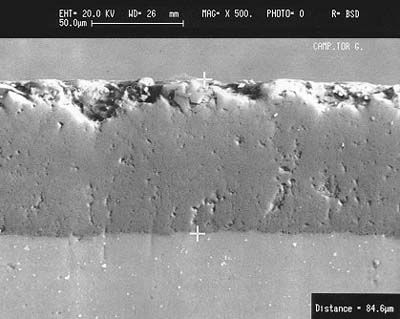

Keronite coating involves creating a high-energy plasma discharge around a component immersed in an electrolyte that provides for surface oxidation as well as possibilities for elemental co-deposition. The layers produced are largely amorphous and fine polycrystalline aluminae (see fig 1). Electrolyte composition and process parameters can be adjusted to tailor layer hardness and toughness. A bath of 200l capacity with a power rating of 80kW can coat a substrate 1500cm2 in an area at 1µm min-1. (Coating rates up to 2µm min-1 are claimed on magnesium.)

The process is said to be robust and comparable with anodizing in terms of running costs. The electrolytes are cheaper than those for conventional anodizing and, unlike many anodizing solutions, contain no environmentally damaging components; they can therefore be disposed of via mains drainage systems without further treatment.

In wear-resistant applications, Keronite coatings can be used at thicknesses up to about 150µm on aluminum and titanium alloys, and about 80µm on magnesium alloys. Layers 200-600µm in thickness can be produced where corrosion resistance or electrical insulation is the main requirement. It is said that the process allows a uniform layer to be formed on complicated shapes without cracking; little surface preparation is required (see fig. 2). In addition, worn or damaged parts can be recoated without stripping the damaged coating.

Coating of deeper holes or bores might require special jigging and electrodes. Best results are obtained on aluminum alloys containing <10%Si, but, unlike the situation with hard anodizing, other alloying elements, such as copper, are beneficial to coating hardness and wear resistance. Best results on titanium and magnesium are obtained on alloys rather than the pure metal. Keronite coatings can also be applied to the specialized Al-Be (AlBeMet-type) alloys that are increasingly being used to save weight in aerospace and high-performance automotive applications. Some typical coating thicknesses and hardnesses are given in the table, although micro-hardnesses up to 2000HV have been achieved on 2xxx series aluminum alloys.

Because the coating is formed through a reaction that involves the substrate, adhesion is excellent. Surface growth is approximately 30 percent of the coating thickness. As deposited (see fig. 1), the coating consists of a thin transitional layer between substrate and coating, a compact layer with low porosity, and an outer layer characterized by higher (>15%) porosity levels. For some applications, the outer layer should be ground or polished away, but the porosity can provide keying for further layers applied to optimize performance. Secondary treatments include coating with PTFE to reduce friction (sliding coefficients as low as 0.1), polymer sealants to increase corrosion resistance and impregnation with nickel, chromium, copper or carbides such as Cr3C2.

Ball on disc tests have shown that the adhesive wear resistance of Keronite on aluminum alloys, particularly 2024, is superior to that of hard chromium layers and an order of magnitude better than hard anodizing, electroless nickel or Ni-Cr3C2 coatings. Coated 6082 aluminum alloy has survived over 2000h in salt spray tests; high copper alloys perform less well (200h), but their performance can be improved by polymer sealing. The layers exhibit good thermal resistance – coatings can withstand short exposures up to 2000°C, which makes them ideal for parts such as rocket venturi, and prolonged exposure to high temperatures is said to have no adverse effect on the coating performance, save for crazing of the surface. Keronite layers also provide suitable substrates for mounting electrical components. Breakdown voltage is typically 10Vµm-1, and can be increased further by impregnation with silicon varnish. The unvarnished insulating layers can operate at temperatures up to 500°C.

Applications

Extensive trials have been undertaken in the textile industry where components treated include spin rotors, fiber guides and twisting devices. A polished Keronite coating impregnated with PTFE has provided abrasion resistance coupled with good friction properties. Benefits have also been found in the use of coated aluminum shuttles for use on looms – these components are conventionally made from high-speed steel and the lightweight aluminum replacements both reduce energy consumption and provide better inertial response.

Other potential applications include pistons, valves and bore linings, exhaust manifolds, hydraulic systems, pneumatic systems, propellers, nozzles and sensors. Use of the coating as a pre-treatment for magnesium alloys may open up large markets in both structural and decorative applications where these alloys are being considered to reduce weight.

For more information, contact Dr. Pavel Shashkov, Isle Coat Ltd., CFB House, 6-10 Malew Street, Castletown, Isle of Man.IM9 1AB UK Phone +44 (0) 1624 825472 Fax +44 (0) 1624 825660. Email pshashkov@cfbtech.com; www.isle-coat.com.

Contract Coaters can be reached at: www.poeton.co.uk/pands/coatings/a3000.htm and www.microncoatings.it/keronite.html/

Ed. Note: This article is provided to Surface Finishing.com by The Institute of Materials Surface Engineering Magazine, a UK publication devoted to all things involving surface finishing. It originally ran in the November, 1999, issue of that magazine. You can check out The Institute of Materials at www.materials.org.uk.