SUR/FIN 2000: C.J. Saporito introduces CompCote composite anodic finish

CompCote offers enhanced abrasion resistance, superior smoothness, excellent corrosion resistance and improved thickness among other attributes. It is a modification of three standard aluminum anodizing processes and, therefore, the films they leave behind on the substrate. The difference between CompCote and Types II and III hardcoat anodizing processes is evident in the columnar structure of the resulting film.

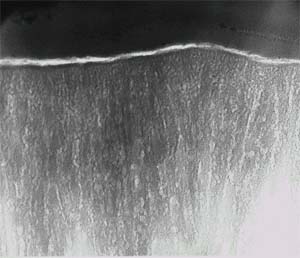

TEM image of the near surface microstructure of CompCote.

Although the basic CompCote film microstructure follows the typical columnar "lanes" associated with hardcoat anodizing films, the new film's cellular structure differs from the long, flat columns found in the latter processes. This allows the "cells" to follow a less uniform path to the substrate and, therefore, increasing corrosion resistance.

For more information on the chemistry involved in the development of CompCote as well as the testing procedures performed by Runge and her team, click here.

C.J. Saporito also supplies plating services, anodizing services (in addition to CompCote), precious metals plating and magnesium finishing processes as well.

For more information, contact C.J. Saporito Plating Co., 3119 South Austin Ave., Cicero, IL 60804. Phone 1 (708) 222-5300; Fax 1 (708) 780-0741.

By Marie Pompili